iRLPD Moisture Damage Test

(incremental Repeated Load Permanent Deformation)

- Sample size: SCB 150-mm x 50-mm

- Applies incremental repeated load before, during, and after conditioning

- Determines minimum strain rate (m*)

- Test Temperature: 25°C

- Moisture damage is determined by the ratio of m* (after to before).

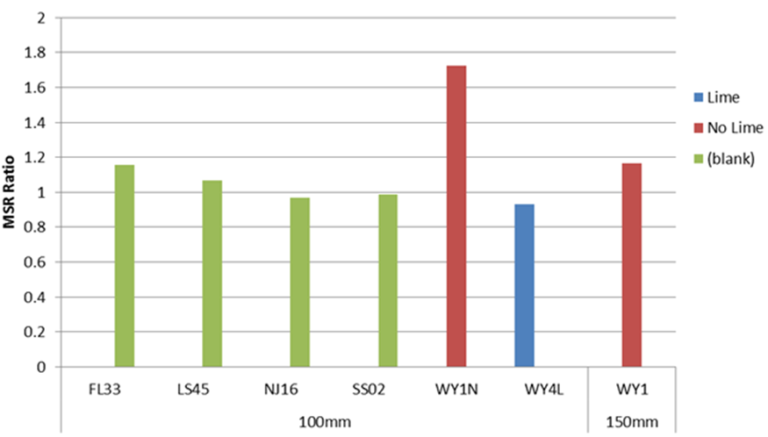

- m* ratio >1.5 indicates moisture susceptibility

Advantages

- Damage is caused by pore pressure, which is related to field

- Higher precision since same specimens used before and after

- Sample preparation and testing time is reduced by 80%

- Total conditioning and testing time is 4 hours

- Better assessment of moisture resistance by using smaller sample size

- Verified with moisture susceptible and moisture resistant mixtures

Reference:

Azari H., Mohseni A., (2013), “Improvement of the Test Method for Determining Moisture Damage Resistance”, Multi-Scale Modeling and Characterization of Infrastructure Materials, RILEM Book Series,Vol 8. Springer, Dordrecht